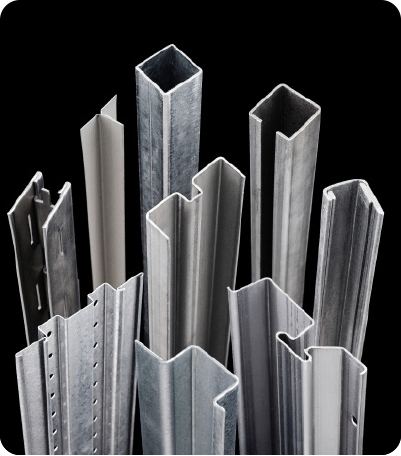

With extensive experience in roll-forming, Superior Sections offer products to suit varying markets and sectors. We help create cost-effective bespoke sections for optimal product and project solutions.

Our bespoke steel sections process

Each and every product we create is designed to offer the most efficient and cost-effective solution.

Added-value, in the form of extra detailing or operations can be included within the roll-forming process thanks to our investment in the latest technology and machinery. Processes such as piercing, notching, embossing, swaging and cutting to length are all options for in-line manufacture.

Where further additional services are required, such as thread inserts, laser-cutting, powder coating, painting and galvanising, we can offer these services too. Just tell us your full requirements when enquiring about your bespoke section needs and we will provide a comprehensive one-stop shop offer by return.